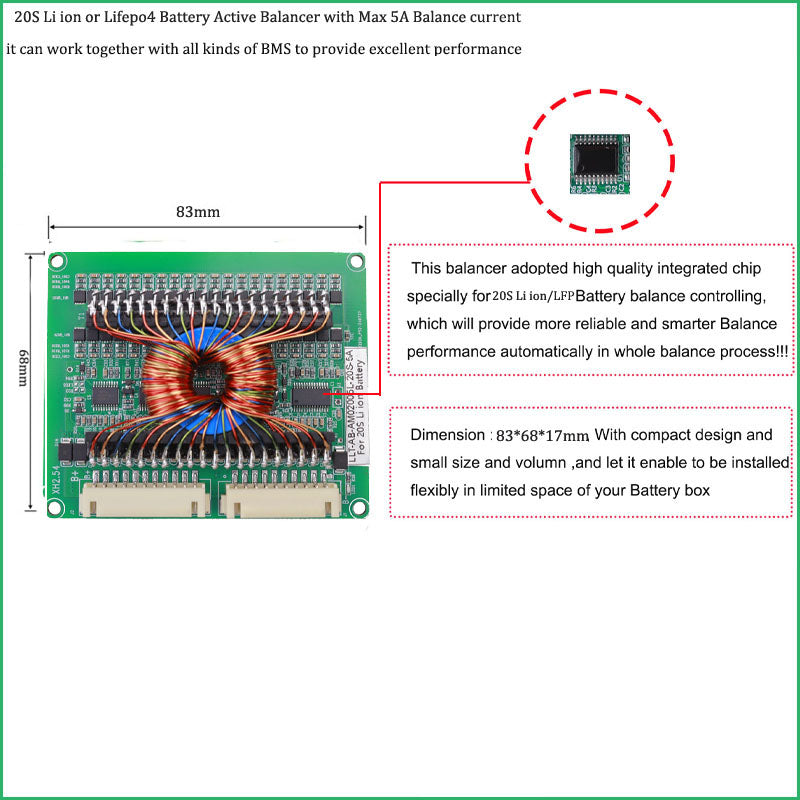

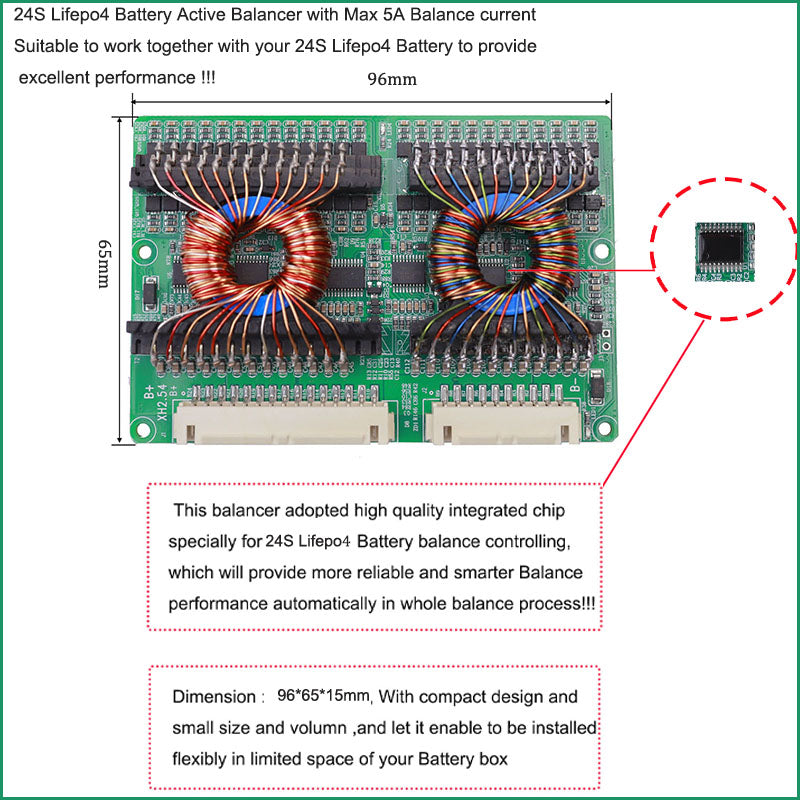

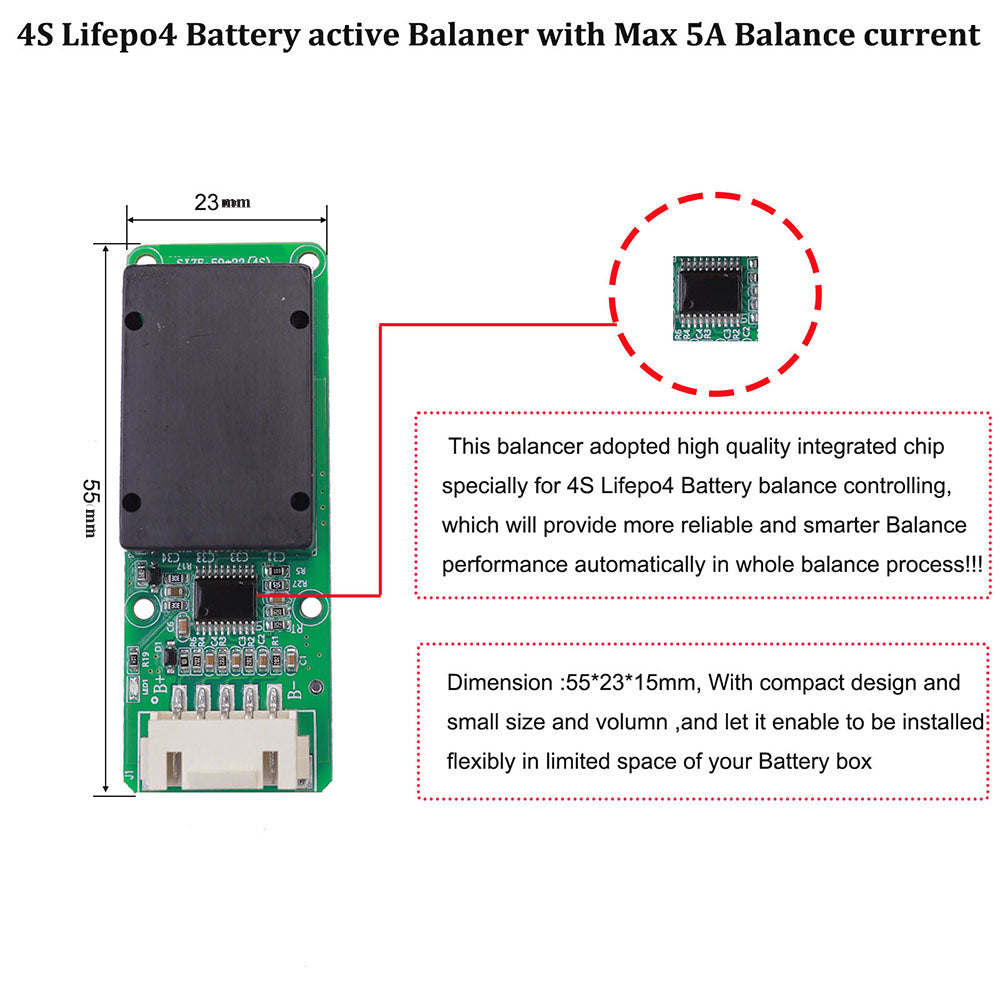

Li ion or Lifepo4 Battery Active Balancer module with 5A to 10A Constant balance current for 12V 24V 36V 48V 60V 72V Li ion or Lifepo4 active balancer with 5A Balance current - 4S Lifepop4 BMS 100A with 5A Balance

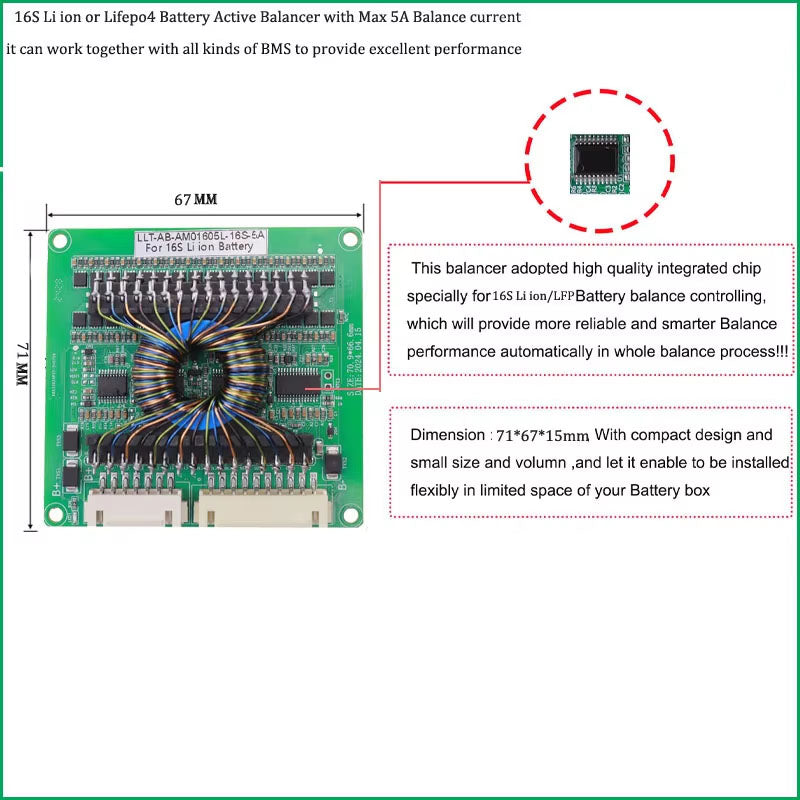

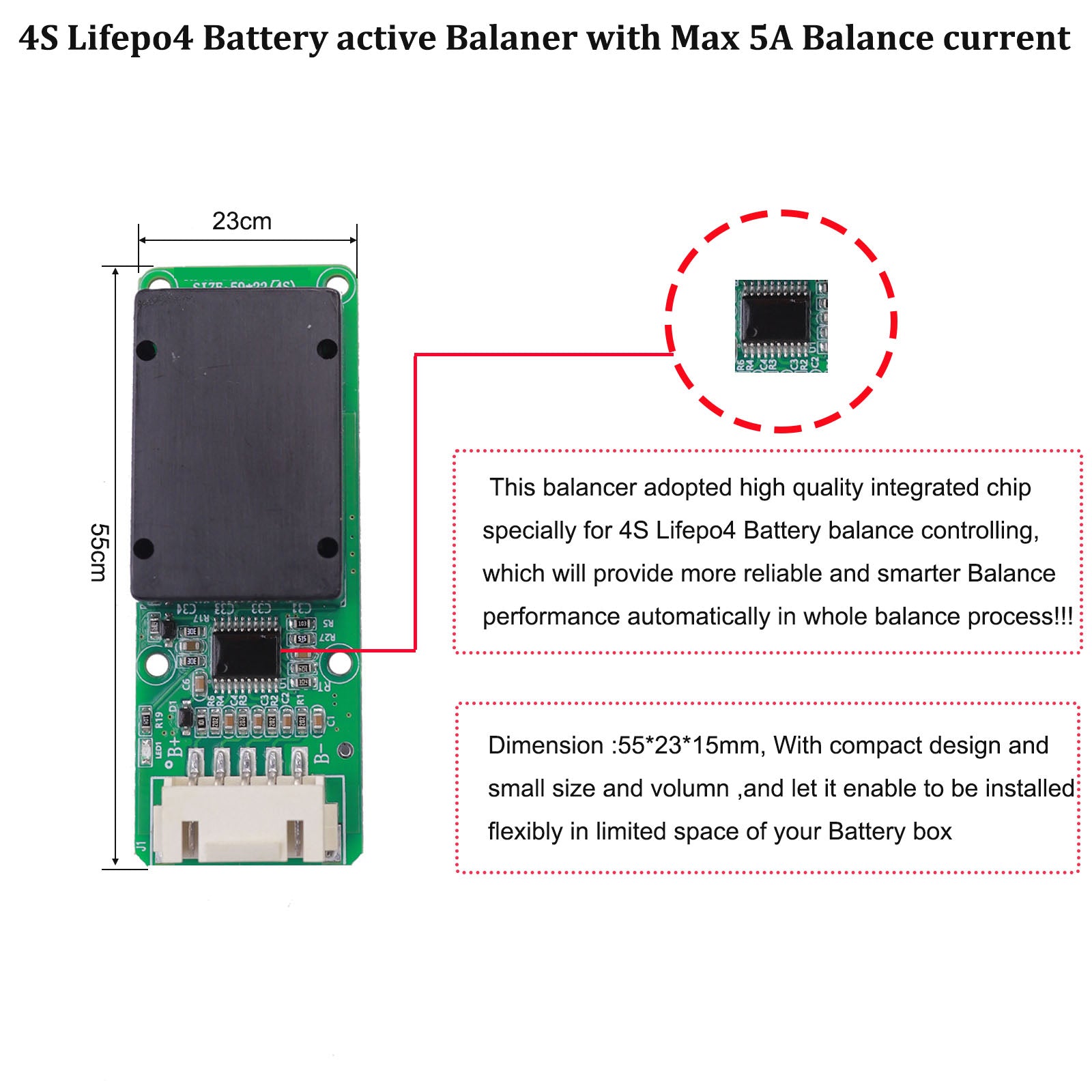

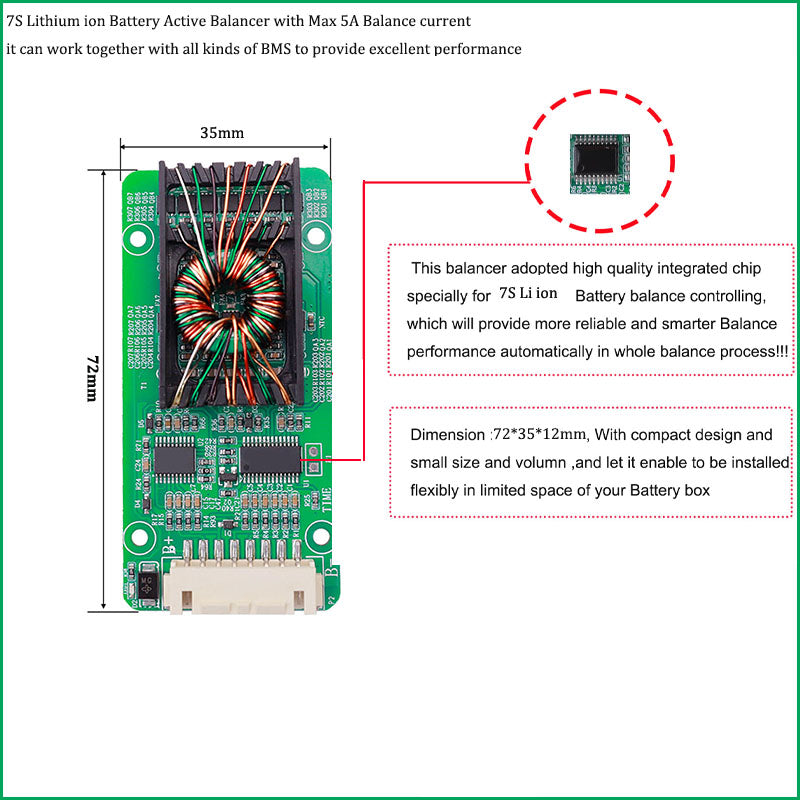

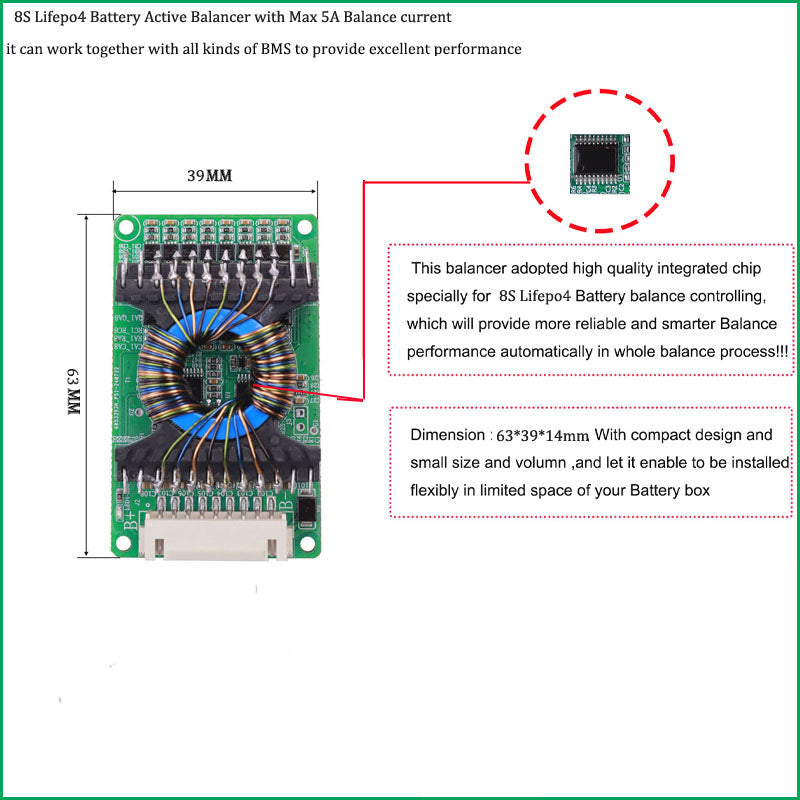

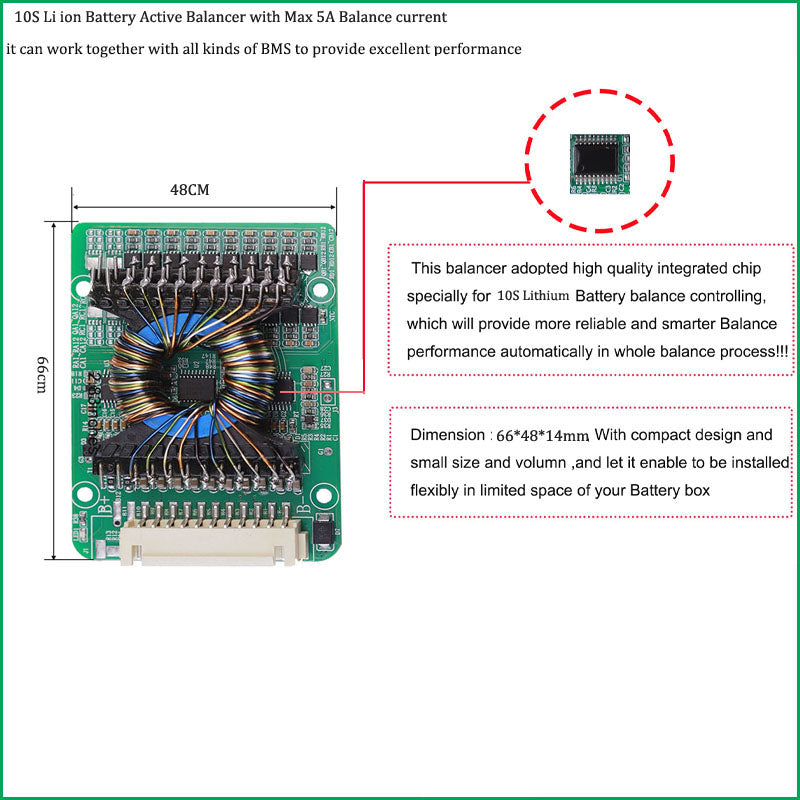

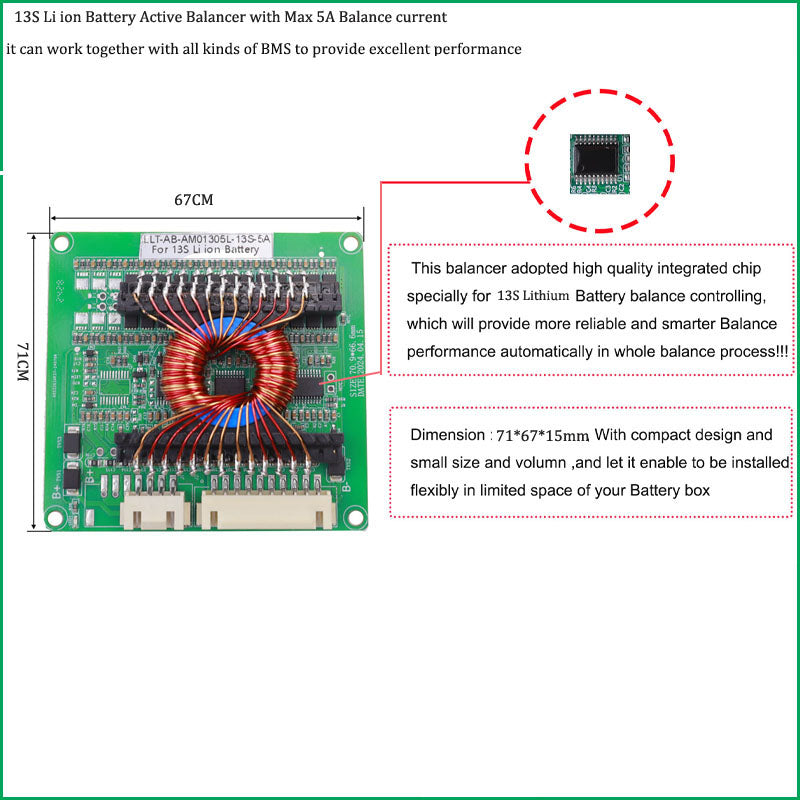

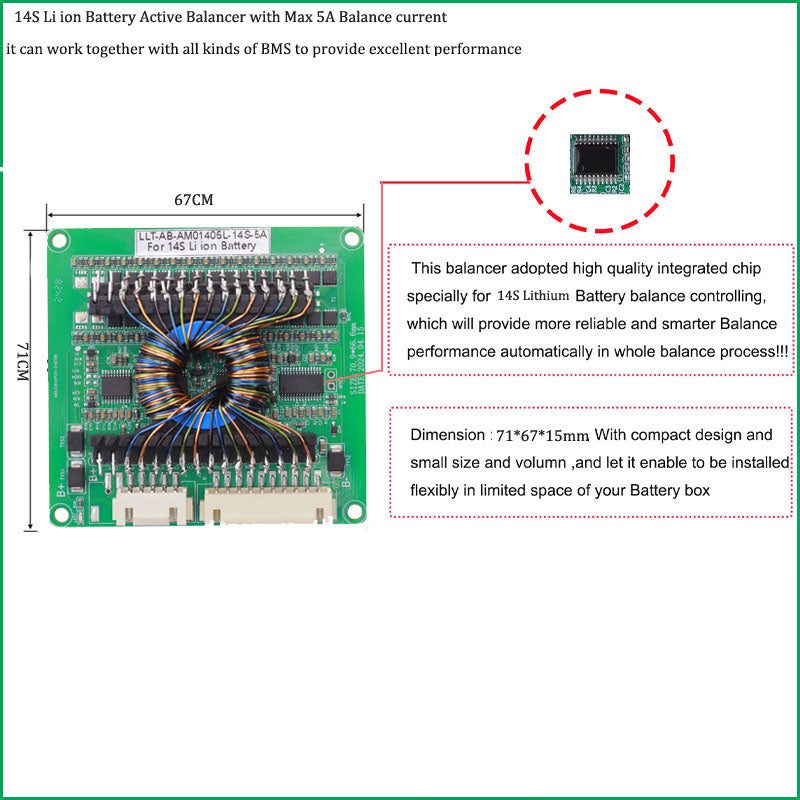

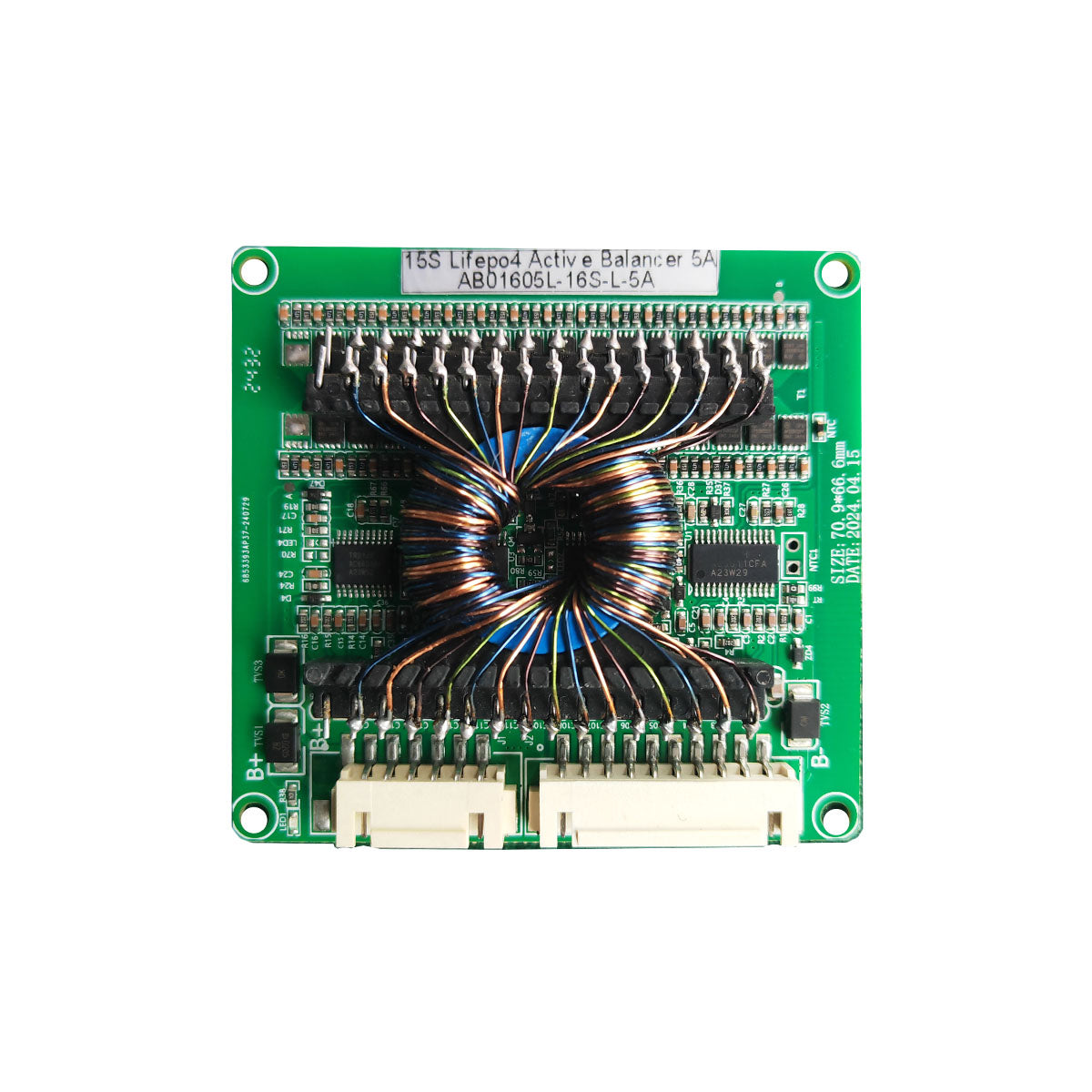

This is The Active Balancer and equalizer for (4S 7S 8S 10S 13S 14S 15S 16S 20S 24S li ion or lifepo4 battery ),client can select suitable models based on your battery specification and battery chemistry features . balance modules can be in series to work for more series battery with our connection diagram also for flexibly application for large battery system balance purpose .

1) Adopted high end integrated controlling chip with intelligent algorithms which will automatically keep your battery system in idea condition with good balance performance.

our active balancer will balance all lower cells by transferring energy from whole system average voltage to lower cells with our unique dynamic algorithm, the balance current will be adjusted automatically based on voltage difference,it is unlike normal neighbouring balance mothods in our current market .

2)Balance precision degree reach less than 10mV,and power consumption in working status reach less than 250mW, and it automatically went to sleep mode once balance work finished ,with less than 0.5mW power consumption .

3) Balance start conditions : when cells voltage difference reached more than 45mV ,( also it should meet balance stop conditions ) then , the balancer will start Balance , the Balancer will

stop work where meets any one of these below conditions .A. cell everage voltage reached below 2.7V±0.05V ( for Li ion cell ) and 2.35V±0.05V for lifepo4 battery B. if single cell voltage reached below of 2.7V±0.05V ( for Li ion cell ) and 2.35V±0.05V C.if cell voltage difference reached below than 45mV .the module will automatically stop work to prevent any possible current drain or overdischarged problems which would hurt the health of the Battery system .

4) With Compact size in design comparing other normal Balancer , our Balance can be installed and work together with your BMS which can save your precious installtation space .

5) Comparing with Capacitor balance , our balance method can greatly low the energy loss and offer big balance current ,provide more safe balance solution for the battery system,and will never harm the low capacity cell’s life so as to keep your whole system in good healthy with real consistency .

6) It can significantly improve your cells consistency and therefore improve your battery capacity and work life time.

7) With high safty and low Power consumptions , can be installed inside of the battery system to work with battery in whole life to greatly improve battery compensive performance such as capacity and voltage .

8)modules can be connected in series to work for more series battery with our connection diagram

Why does the Lithium Battery needs Balance ?

To talk about balance, we have to start with the battery. Even batteries produced in same batches by the same manufacturer have their own life cycles – the capacity of each battery can not be exactly the same. There are two main reasons for this inconsistency:

A. As Normal BMS with Balance ,it usually is a passive Balance with very small balance current , which can not handle all cells effectively in good consistency after few cycles of battery , and the active Balancer will provide an excellent performance for your battery in long run time for keep

all cells in good conditions , and the Max balance current can reach up 5A based on your cells voltage difference .

B.Inconsistency in production

The inconsistencies in production are easy to understand. For example, during the production process, the separators are inconsistent, and the cathode and anode materials are inconsistent, which resulting in inconsistencies of overall battery capacity. For example, the production standard with a batch batteries with 2.5AH , But after the production it may become 2.4 AH,also it may be 2.6AH.

This board operates on the principle of adjacent equalization for battery system ( Li ion or Lifepo4 ). it should be applied together with Battery BMS. The pressure difference resulting from charging and discharging which will triggers the operation of the Balancer board to achieve energy transfer equalization.

C . Electrochemical inconsistency

Electrochemical inconsistency occurs during the battery charging and discharging process. Even if the production and processing of the two cells are exactly the same, the thermal environment can never be consistent during the electrochemical reaction. For example, when making battery modules, the surrounding temperature of battery system will be definitely lower than middle position , which will cause long-term inconsistency in charge and discharge and therefore causes inconsistency capacity with cells , and when the separator film of the battery has imbalance charging and discharging currents for a long time, the battery separator will aged.therefore takes Inconsistence.

Battery inconsistency will affect the performance of the battery pack. Battery packs which were connected in series and follows the short- board effect of the barrel. for battery pack system connected in series, the capacity of the entire battery pack is determined by the lowest cell’s capacity, which results in:

1. Reduce the actual available capacity of the entire battery pack.

2. when The life of the battery pack is reduced, and the capacity is reduced,which will need to increase more times of charge and discharge cycles to let battery work, which will short battery life further.

3. safety performance will be seriously affected when battery consistence were terrible .

Our advantages with active Balance :

Our professional Power management chip which integrated battery overcharge, over-discharge, over-current, short circuit, disconnection, temperature detection and other protections

With large active balancing current, the balancing current can reach up to 10A, and the balancing voltage precision can be within 5mV.

Active will work in those process: 1. Active Balance will work throughout the whole charging process. 2. Controllable Balance in standby process, 3. Automatically starting balance when the voltage difference between cells exceeds 45mV

It solved the problem of low cycle times and short service life of battery packs due to inconsistent battery capacity, voltage difference, and internal resistance difference, making the product safer and more reliable, therefore prolong whole battery work life

significantly .

Solve the problems of low efficiency, small balancing current of general passive balancing methods. The application fields include power tools battery, photovoltaic battery,

Outdoor energy storage battery , battery replacement cabinets, electric bicycles battery ,or EV battery etc.

balance modules can be connected in series with this below example to work for more series battery ,(please consult us for other series module connection methods for 4S 7S 8S 13S 15S 16S 20S 24S etc)